We have completed a project for chemicals sourcing from Taiwan.

When we received the inquiry, it felt like Déjà vu because we have gone through the same topic when RCEP was signed. Is RCEP going to affect Taiwan or your business?

RCEP took a great impact on our Petrochemical industry in Taiwan, and now we had the chance to source related products for our customer and put all the pieces together.

This time we are assigned to source 3 chemicals from Taiwan, they are BOPP, DOTP and Phthalic Anhydride from two different suppliers. To start with, we need to understand what chemicals are.

What are called chemicals?

There are 3 types of chemicals

- Commodity Chemicals

- Fine Chemicals

- Specialty Chemicals

What is the industry like?

Taiwan has been played an important role in Petrochemical industry since war II, in 1957, Formosa Plastics Group (FPG) built the first plant in Kaohsiung, Taiwan, they focused on PVC. Back then, plastic was not wildly used in Taiwan yet. To fulfill the increasing demands of plastics, Taiwan started to develop the supply chain. At first, they started with plastics and rubber processing, so called downstream. As the downstream processing got more mature, plastics became common and dominant in Taiwan.

The industry can be categorized into 3 groups,

- Upstream: crude oil, gasoline, diesel, lubricating oil, and drilling equipment.

- Midstream: It is the basic petrochemical raw materials produced by the cracking of upstream raw materials, such as ethylene, propylene, butadiene, benzene, phenol, etc. Plastics, rubber and artificial fibers are made by above chemicals through chemical reaction.

- Downstream: the products that are made after processing plastics, rubber and artificial fibers, such as: plastic products, rubber products, detergents, artificial fibers, paint, adhesives, plasticizers, pesticides and cosmetics.

The reason petrochemical industry succeeded in Taiwan was because of the developments from the downstream. Starting from processing plastics, rubber and artificial fibers, Taiwan then import Petrochemical raw materials to develop the midstream. Lastly, naphtha cracking plants were built to develop the upstream. Players like Formosa Plastics Group (FPG) is the world’s sixth-largest chemicals producer, with more than 110,000 employees and sales last year of US$77.5 billion. Formosa and CPC Corp. dominate the local petrochemical sector, focusing on the production of raw materials like olefins and aromatics.

What is Taiwan’s strength?

As China and Southeast Asia took over the upstream sector, Taiwan no longer has its advantage of producing highly polluted petrochemical products. The continuous protections and the damage to the high density of population environment has become more and more clear. Taiwan is not supposed to build more naphtha cracking plants. The ongoing protests have not stopped since FPG built their Mailiao plant.

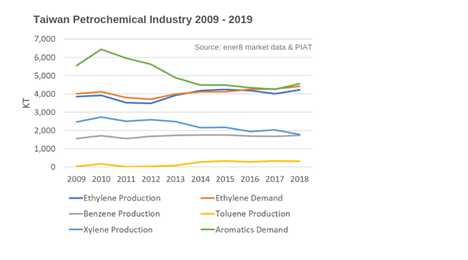

By far, Taiwan operates 5 naphtha crackers with a total ethylene capacity of 4.0 million mt per annum. CPC operates two naphtha crackers in Linyuan with a total ethylene capacity of 1.0 million mt per annum, while Formosa has three naphtha crackers at their 2,603 hectares complex at Mailiao with a total ethylene capacity of 3.9 million mt per annum. The current five crackers were built in 1984, 1998, 2000, 2007 and 2013.

What’s next after protests?

Building more cracking plants is a no-go in Taiwan, which means the upstream is going to face challenges to produce in even more larger scale. This results in relocation for companies such as, Formosa Plastics Corp(FPC) to seek for foreign investment in the US. The industry in Taiwan has begun to switch to other sector- specialty chemicals.

In the past few years, Taiwan’s petrochemical industry has started to focus on high-tech specialty chemicals that are used to produce multidimensional high-tech products.

Specialty chemicals, also called performance chemicals, generally don’t constitute the bulk of the material in the end product, but instead are usually added in small quantities to affect changes in the properties or performance of a product, such as HSBC (hydrogenated styrenic block copolymer).

This time, we dive into the world of chemicals to understand the use of the chemicals and the situation in the industry.

What did we source for the customer? DTOP, BOPP and Phthalic Anhydride.

- DOTP (Dioctyl terephthalate)

DOTP is an excellent plasticizer with excellent electrical and thermal property, It has uses in applications like extrusion, injection molding, rotational molding, dip molding, slush molding and coating. We can use it on products such as cables that requiring heat resistance and high insulation.

When we sourced DOTP, one supplier brought up the issue that it’s been out of stock due to the huge demand of electronics during the pandemic. Thanks to the increasing needs of personal laptops and video conferencing devices, DOTP has been a popular chemical for manufacturing cable, which is the peripherals of most electronics. DOTP will continue showing its importance to electronic manufacturers, and we only know that it will get more and more popular in the digital world.

2. BOPP (Biaxially oriented polypropylene)

BOPP is such a mysterious chemical, originally from PP (Polypropylene). PP is used in a wide variety of applications.

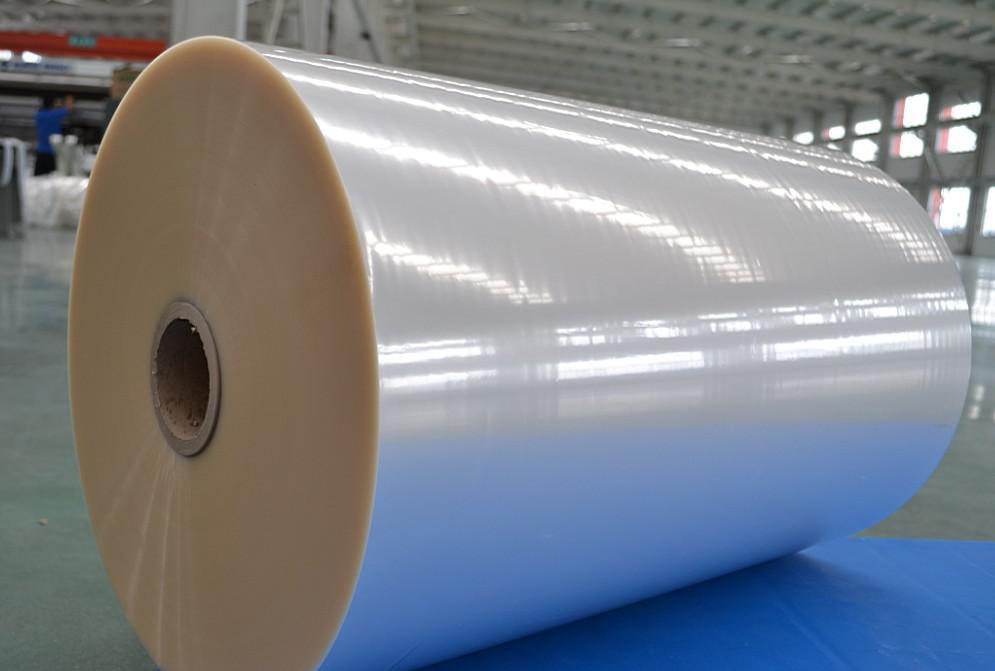

When polypropylene film is extruded and stretched in both the machine direction and across machine direction it is called biaxially oriented polypropylene. Two methods are widely used for producing BOPP films, namely, the tenter process and tubular process. BOPP is widely used as a packaging material for packaging products such as snack foods, fresh produce and confectionery. It is easy to coat, print and laminate to give the required appearance and properties for use as a packaging material. This process is normally called converting. It is normally produced in large rolls which are slit on slitting machines into smaller rolls for use on packaging machines. BOPP is also used for stickers and labels, including by commercial sellers such as Sticker Mule.

Due to the multiple functions of BOPP, when we speak with suppliers, they requested to indicate the applications in order to quote the right type of BOPP. In this project, our customer inquired BOPP for packaging of muesli. BOPP has excellent resistance to water and can perfectly attach with ink, therefore, it’s also largely used in printing water-proof stickers.

Taiwan has many players for BOPP, there are also many retailers in the market because of the high commercial value and function.

3. PA (Phthalic Anhydride)

PA is also a plasticizer, it is an important industrial chemical, especially for the large-scale production of plasticizers. In 2000, the worldwide production volume was estimated to be about 3 million tons per year. It can also be used in manufacturing dyes and medicines.

What are the challenges during sourcing?

We have faced some significant issues during our sourcing process, there are three main challenges,

- Thorough research on customer’s inquiry: our customer has been active in chemical industry for many years, when they approached to find suppliers, our first job was to understand what they are talking about. The industry is tremendous and each supplier has its own specialty, without research, we can easily approach to the wrong suppliers and show unprofessionalism.

- The difficulties of reaching out to the key person due to the big scale of the company: all the companies in petrochemical industry are the same, they are very big with numberous departments. It did take us a while to find the right persons to gather the quotes from different companies. The key is to specify what we are looking for preciously and allow them to take time searching for the right contacts.

- High sea freight rate: in the industry, products are sold in MT, which means they are transported by sea freight. Due to the high sea freight rate this year, many buyers have been having issues making profits out of imported chemicals. However, suppliers are also suffering from it. With the high sea freight rate, Taiwanese suppliers are losing the battles in competing with Korean suppliers regarding prices. They are also unable to offer quotes due to lacking of containers.

Though it went more smooth than we expected, all the suppliers in Taiwan are very friendly and nice to deal with. We are very grateful for our client’s patience and the kindness of the suppliers even in the tough period of time.

Just sharing…

As we close more projects, the journey has become more fun. The main reason is that we find similarities in different industries, and the experiences and connections we have gained through different projects are accumulating. It has totally changed the way we thought about one industry from one angle, as when issues and challenges occur, we have had different approaches to overcome and resolve.

We are now more excited to put more puzzles together for you!

Ask Taiwan, your dependable sourcing and business partner in Taiwan

Reference:

1. https://en.wikipedia.org/wiki/Polyvinyl_chloride

2. https://www.taiwannews.com.tw/en/news/1349124

3. https://www.ener8.com/taiwan-petrochemical-industry-outlook

4. https://topics.amcham.com.tw/2017/04/moving-specialty-chemicals/

5. https://en.wikipedia.org/wiki/Dioctyl_terephthalate

6. https://en.wikipedia.org/wiki/Polypropylene

7. https://en.wikipedia.org/wiki/Phthalic_anhydride